In today’s data-driven economy, organizations are actively searching for AI business process optimization solutions that not only automate workflows but also sustainably enhance performance and profitability.

Yet many companies fall into the trap of focusing on automation alone—without addressing the foundational measurement and management systems that determine whether AI initiatives deliver measurable value.

At Smarter Solutions, Inc., our Integrated Enterprise Excellence (IEE) methodology provides a structured, data-based framework that connects AI, business process optimization, and performance metrics into one coherent system.

Rather than offering a patchwork of tools or dashboards, IEE aligns AI initiatives with enterprise-wide improvement strategies, creating sustainable value streams that directly link process metrics to financial outcomes.

Performance Metrics for Process Optimization

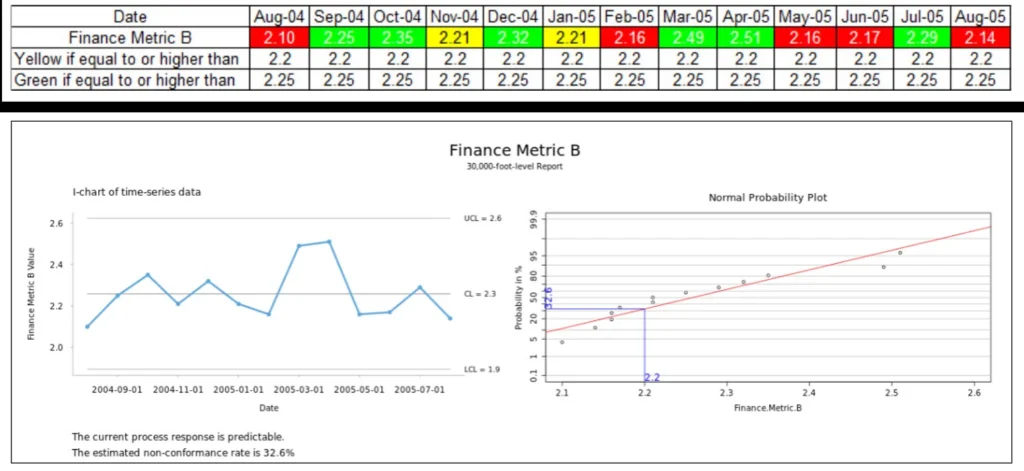

Traditional management systems often rely on red-yellow-green scorecards and tables of numbers to monitor performance. While visually simple, these tools create ambiguity: is the process truly improving, stable, or degrading? Such subjective assessments make it nearly impossible to align AI initiatives with true business needs.

The IEE approach replaces these outdated visuals with 30,000-foot-level performance metric reports, which offer a statistically valid, predictive understanding of process behavior. Using this method, organizations gain a clear, data-driven picture of whether a process is performing consistently and whether future outcomes will meet desired goals.

With our free 30,000-foot-level app, anyone can create these reports directly from an existing Excel spreadsheet containing process output data—whether it’s normally distributed or log-normal. The app translates raw process metrics into statistically meaningful trend charts that reveal whether changes are significant or simply random noise.

Once an undesirable predictive statement is identified—for example, when a metric’s forecasted outcomes fall short of targets—this signals the need for business process optimization. AI-driven tools can then be applied to optimize or redesign processes that truly require improvement, rather than wasting resources on stable systems.

The result: enterprise-wide clarity on which processes to improve, when to intervene, and how to measure impact—without subjective interpretation.

To illustrate the power of 30,000-foot-level reporting, consider the red-yellow-green scorecard of Finance B that was reported in an organization and its 30,000-foot-level report alternative.

Scorecards are to create actions are non-actions at some point in time.

We would like for the BEST actions are non-actions to be suggested; however, often (in the real world) this does not occur because of how the data are presented.

Actions that the red-yellow-green scorecard can create are at each point in time where a color was red is “get someone out there to fix the problem that our metric is not meeting its management-created objective.”

The 30,000-foot-level report for the same dataset shows in the individuals chart (left graph) that there was no improvements in the metric over time (e.g., from the red-yellow-green scorecard actions) and the process output response is stable (hence predictable).

The right graph of the 30,000-foot-level report shows that the normal distribution is a good fit for making a futuristic statement of the expectation for the process output, if nothing were to change.

From this probability plot, we can determine the expectation for the response to be about 33% of the time to be below the 2.2 criteria.

With a 30,000-foot-level report, this “non-conformance” process capability statement is stated at the bottom of the report-out.

With a 30,000-foot-level report format, our action plan completely changed from firefighting red-signal common-cause noise variation to undertaking a business process improvement effort – if we considered a 33% non-conformance rate to be unacceptable.

When someone first examines a 30,000-foot-level report, they might state that this report format is too complex to understand.

HOWEVER, a 30,000-foot-level report is MUCH easier to understand when determining the BEST action or non-action to undertake!!

After someone overcomes the initial intimidadition of the different appearance of a 30,000-foot-level chart they can see, for example, when a process is stable or not. If a process output response is stable and a prediction statement is undesirable, there is a need for a process optimization effort.

Red-yellow-green scorecards DO NOT provide this information about the need for process optimization.

Six Sigma in Business Process Optimization

AI-driven business improvement initiatives are most powerful when grounded in proven methodologies—and none are more enduring than Six Sigma. However, the Integrated Enterprise Excellence system takes Six Sigma principles to the next level by integrating them with business strategy and predictive measurement.

Organizations that implement Six Sigma within the IEE structure find that their improvement projects are no longer isolated technical exercises; instead, they become strategic investments directly linked to enterprise performance goals.

For those seeking structured guidance, the following books by Forrest W. Breyfogle III offer comprehensive roadmaps for deploying Six Sigma within a business process optimization context:

- Integrated Enterprise Excellence, Vol. II – Business Deployment: A Leader’s Guide for Going Beyond Lean Six Sigma and the Balanced Scorecard

Explains how leaders can create a culture of improvement that aligns Six Sigma and Lean with organizational strategy. - Integrated Enterprise Excellence, Vol. III – Improvement Project Execution: A Management and Black Belt Guide for Going Beyond Lean Six Sigma and the Balanced Scorecard

Provides detailed tools and project execution techniques to ensure Six Sigma projects deliver financial and strategic value. - Lean Six Sigma: A Handbook and Solutions Manual for Green Belt, Black Belt, and Master Black Belt Process Improvement Projects (2-book Bundle)

Serves as a comprehensive reference and training guide for all levels of Six Sigma professionals.

These resources enable organizations to develop an internal capability for Six Sigma in business process optimization, where AI tools complement data-driven analysis rather than replace it.

When combined with IEE’s 9-step system, Six Sigma becomes part of a holistic business management framework that eliminates silos, drives accountability, and ensures that every process improvement contributes to bottom-line results.

Process Optimization Strategies

Many organizations introduce AI and process automation without a strategic roadmap for where and how these tools will produce the greatest ROI.

The IEE methodology changes that paradigm by embedding process optimization strategies directly into business governance structures.

Using Smarter Solutions’ Enterprise Performance Reporting System (EPRS) software organizations can:

- Automatically update 30,000-foot-level metrics daily, creating a live, data-driven management dashboard.

- Prioritize improvement initiatives based on true process need, rather than management opinion or urgency bias.

- Identify where AI and machine learning can best enhance predictive accuracy, efficiency, or customer experience.

- Visualize process performance across departments, ensuring systemic alignment rather than isolated improvements.

This integration allows AI to serve as a strategic optimization engine rather than a disconnected analytics layer.

By knowing where process variability or waste exists, companies can apply AI precisely where it will deliver measurable business outcomes.

Reiterating, this structured approach to process optimization strategies makes AI more effective within organizations—a theme explored in Forrest Breyfogle’s keynote presentation, Implementing AI in Business: Reducing AI Implementation Risks.

As described in that presentation, organizations that align AI deployment with IEE measurement systems achieve sustainable, enterprise-wide transformation.

Process Optimization Consulting

Even the most sophisticated AI tools or Six Sigma projects can falter without expert guidance on systemic alignment. That’s where process optimization consulting through Smarter Solutions, Inc. adds tremendous value.

Our consulting approach goes beyond technical fixes. We help organizations:

- Build an integrated measurement-to-improvement system across departments.

- Identify which processes most impact strategic goals and where AI can accelerate improvement.

- Create a culture of data-driven accountability, where every team member understands how their work affects enterprise results.

- Establish predictive dashboards that connect daily process performance to financial and operational outcomes.

By coupling IEE’s 9-step framework with AI technologies, our consulting ensures that improvement efforts are sustainable, scalable, and strategically aligned.

When organizations adopt IEE-based AI business process optimization consulting, they gain more than technical capability—they gain a system for continuous improvement that evolves as their business does.

Sustainable AI transformation isn’t about adopting more software; it’s about creating a management system where data, process metrics, and improvement strategies work in harmony. Smarter Solutions’ Integrated Enterprise Excellence framework provides that system.

By using AI business process optimization solutions rooted in IEE principles—supported by 30,000-foot-level metrics, Six Sigma discipline, and strategic process optimization strategies—organizations can achieve what most digital transformations fail to deliver: predictable, profitable, and measurable enterprise performance.

Next Steps

If your organization is:

- Frustrated by reacting to dashboard noise

- Tired of inconsistent improvement efforts

- Ready to make data a driver of strategy

- Set to enhance your AI efforts

…then it’s time to explore an IEE approach for Implementing Edwards Deming Theory with Smarter Solutions.