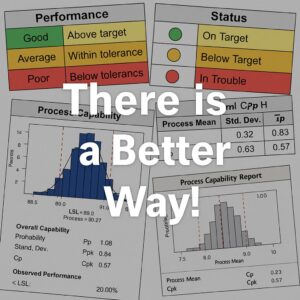

Organizations need to be able to calculate process capability when there is no specification; however, the traditional process capability indices of Cp, Cpk, Ppk, and Ppk require a specification.

A process capability specification is to be customer driven; however, not all processes have true customer derived specifications. Process output responses that do not have a true specification (a goal is not a specification) cannot provide a capability statement using traditional Cp, Cpk, Pp, and Ppk reporting techniques.

The easiest method to report the capability of a process without a true specification is to report expected typical values. When no specification exists (goals are not a specification), an Integrated Enterprise Excellence (IEE) Business Management System 30,000-foot-level metric reports a median (or mean) value followed by a 80% range of occurrence (+/-40% from median or mean) [for stable processes]. Why 80%, no real reason, it could have been a 90% or 95% range just as easily. We believe that an 80% range of occurrence is close to what a person may view as a typical response.

Process Capability Reporting and Process Improvement

The philosophy of the IEE system with its 30,000-foot-level reporting is:

- If a process output response is stable from a high-level (30,000-foot-level) viewpoint, the process is predictable, and the report-out will provide a prediction statement. Note: The 30,000-foot-level nomenclature is an analogy to the view of the terrain below from an airplane at 30,000 feet.

- When there is a specification (e.g., a critical dimension on a produced product), a process output prediction statement (at the bottom of the report) will provide an easy-to-understand, estimated non-conformance rate.

- When there is no specification (e.g., volume of a product produced weekly), a process output prediction statement (at the bottom of the report) will provide an estimated mean or median response with 80% frequency of occurrence

- When a prediction statement is unsatisfactory to the business or customers, there is a need for process improvement.

- Process improvements to improve a metric response can be made following a clickable Lean Six Sigma DMAIC roadmap or another process improvement technique.

- Demonstration of a process improvement (or degradation) response, whether there is a specification or not, is through the staging of the 30,000-foot-level individuals chart(s) in the metrics report-out

- After a 30,000-foot-level individuals chart(s) staging, a new process capability statement (whether a specification exists or not) will be provided from the after-staging dataset at the bottom of the report-out.

Non Specification Process Capability with an Improvement Goal Criteria

Process Goal

A goal is usually considered as the target for the process output. In most cases when there is no specification (e.g., volume of a product produced weekly) you want the process average to be equal to the goal. In these cases you can report capability as an average response along with an 80% range of common response. For this situation, when the current estimated mean response is not achieving the goal, there is a need for process improvement.

Performance Time goal

This type of target is seen often in Service Level Agreements (SLA) where there is an agreement to not exceed the target more than X% of the time. An example would be a call center that agrees to answer at least 95% of all calls within 5 minutes. Reporting performance to this type of goal has two common methods. One method involves reporting the actual percentage above the target time and comparing to 5%. The second method is to count the days that the SLA is met. These two method consider a continuous measure and then convert it to an attribute before reporting. Both of these methods are preferred by management because they track compliance with a commitment to a customer.

As a rule, I would avoid converting continuous data into an attribute for reporting. In this case you are better served by tracking the actual time measurements. Using each point or a average/std.deviation value for sequential periods would provide you better estimate of the process consistency, then you can use a probability plot to report the estimated long term percentage over the SLA value. If you have a stable process, there is no value in reporting the daily SLA agreement, because you know it will vary randomly and you may trigger firefighting activities due to a randomly high value.

In-process upper/lower specification (not customer derived process capability specification)

This might be the most dangerous condition to deal with due to its impact on the entire corporate quality system. In this case you would have a specification value set for an intermediate process characteristic that is not a final customer requirement. It may be a concentration, a weight, a dimension, or almost anything that you use for process control but not for quality control. The business labels it as a specification, but does not scrap product that exceeds the values. You may rework or touch up, but the product or transaction is still processed.

I consider these values not as specifications but as process limits. The term specification should only be used for customer or contract controlled limits that define good and bad. Shipping a product or providing a service that is knowingly bad is just not done. If you label the in-process characteristic limits as process specifications, you have set up a condition where you may excuse the product or service that exceeded the process specification and keep processing it. This just created a dilemma for the workforce. You allow a product or service to continue when it exceeded a specification value at this process, so why not consider that behavior for all specifications. This is why the work specification should only be used for customer or contract based limits that define good and bad. Use action limits or process limits or some other euphemism that the workforce understands that the process may exceed and we will still continue processing with additional consideration.

In these cases, you should report the percent of the product or service that is non-conforming to the process limit. along with assessing the stability of the process.

Process characteristic that has no specified limit or target

These cases are fairly easy. If there is no target or process limits available, then the goal is to keep the output consistent. Report the mean performance and the 80% range of output as long as the process is stable.

Performance without stability.

I can not write about performance reporting without reinforcing the requirement to assess the stability of a process before reporting the performance or capability. Only use data from the most recent period of stability in all performance reporting. If a process is unstable, do not report the capability.

How to Calculate Process Capability When There Are No Specification Limits? A Smarter Alternative

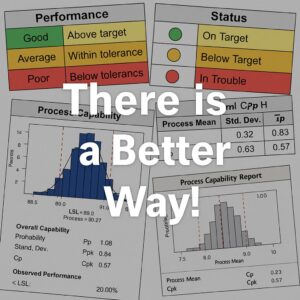

In many operational environments, teams are asked to calculate process capability even when formal upper and lower specification limits (USL and LSL) don’t exist. Traditional Six Sigma tools—such as Cp and Cpk—rely heavily on the presence of these limits. But what happens when your performance goal is directional, such as “the lower the better” or “closer to target is preferred,” without a defined boundary? Most tools fall short. That’s where the Integrated Enterprise Excellence (IEE) 30,000-foot-level approach shines.

The Limits of Traditional Capability Calculations

Calculating process capability typically involves comparing the spread of your process data to the spread defined by USL and LSL:

Cp = (USL – LSL) / 6σ

Cpk = min[(USL – μ) / 3σ, (μ – LSL) / 3σ]

These equations assume normality and control, which may not hold true in many real-life scenarios. Even worse, if your performance measure has only a target or a goal but no hard specs, the above formulas simply can’t be applied in a meaningful way.

For example, imagine tracking time-to-ship orders. Your business goal may be “ship within 24 hours,” but there’s no LSL or hard cutoff. Traditional process capability metrics would either be misapplied or ignored, leaving a gap in performance understanding.

The 30,000-Foot-Level Solution for Calculating Capability

Smarter Solutions offers a better way. The 30,000-foot-level reporting approach begins by evaluating whether the process is stable and exhibits a predictable pattern over time. If yes, capability is reported using a predictive performance metric, such as a long-term non-conformance rate or the percentage of observations exceeding a goal.

Here’s how to “calculate” capability smartly—even without USL or LSL:

Plot Time-Ordered Data – Use a control chart-like format to visualize stability and trends.

Assess Process Stability – If the process is not stable, prioritize improvement rather than capability reporting.

Fit a Predictive Distribution – If stable, fit a distribution (e.g., normal, lognormal) to the data and evaluate the probability of meeting the business goal.

Report Capability as a Predictive Measure – Instead of Cp or Cpk, express performance as “X% of future outputs are expected to meet the goal.”

For instance, if your predictive model suggests that 97.5% of shipments will be under 24 hours, that’s a meaningful capability statement that anyone—executives, managers, or customers—can interpret.

Aligning Capability with Strategy

The 30,000-foot-level approach bridges the gap between operational data and strategic decision-making. It moves capability reporting away from overly technical, potentially misleading metrics and toward practical, actionable insight. By focusing on predictability and alignment with enterprise goals, this method empowers leadership to make smarter, data-driven decisions.

Conclusion about Calculating Process Capability (Without Process Capability Indices) When No Specifications exists

You can’t calculate process capability effectively when you’re boxed into outdated formulas that require full specifications. But with Smarter Solutions’ IEE 30,000-foot-level methodology, you can still quantify process performance—even when you’re working with a business goal instead of a spec limit. It’s a smarter, more insightful way to answer the real question: “Is our process consistently delivering what the business needs?”

Process Capability Calculation Without Specification Limits: A 30,000-Foot-Level Approach

In traditional Six Sigma settings, a process capability calculation is typically based on defined specification limits, assuming the process data is normally distributed and statistically stable. But what happens when you only have a performance goal and no hard upper or lower specification limits? This is a common real-world scenario where the conventional approach falls short. Fortunately, the Integrated Enterprise Excellence (IEE) system provides a smarter solution through its 30,000-foot-level reporting methodology.

The Limitation of Traditional Capability Calculations

Standard process capability indices such as Cp and Cpk use the following formulas:

Cp = (USL – LSL) / 6σ

Cpk = min[(USL – μ) / 3σ, (μ – LSL) / 3σ]

These formulas require upper and lower specification limits (USL and LSL) and assume normal distribution and process stability. Without these conditions, a traditional process capability calculation can be misleading—or not possible at all.

For example, consider a performance goal like “complete order processing in under 2 days.” If there’s no defined lower limit or strict upper spec, how do you calculate capability in a way that provides business value?

The Smarter Alternative: Predictive Capability from 30,000 Feet

The IEE system’s 30,000-foot-level approach addresses this challenge head-on by transforming how we define and assess process capability. Rather than focusing solely on statistical formulas, this methodology emphasizes predictability and relevance to business outcomes.

Here’s how the smarter process capability calculation is performed when only a performance goal exists:

Assess Time-Ordered Data: Begin by charting performance over time. This provides visibility into trends, shifts, and outliers—key indicators of process stability.

Determine Process Stability: If the process is unstable, any capability calculation is premature. The priority should shift to root cause analysis and stabilization.

Fit a Predictive Model: If the process shows consistent behavior, fit a statistical distribution to the data, even if the data is non-normal.

Calculate Predictive Capability: Instead of computing Cp or Cpk, calculate the percentage of future outputs expected to meet the performance goal using the fitted distribution. For instance, “98.5% of future orders are predicted to be processed in under 2 days.”

This forward-looking performance metric provides a practical and business-relevant capability assessment, especially when no hard specification limits are defined.

Bridging Metrics with Meaning

The strength of the 30,000-foot-level methodology is its ability to bridge the technical world of analytics with the strategic needs of the enterprise. A traditional Cpk value may sound technical, but it doesn’t always answer the executive-level question: “Will our process consistently meet expectations?”

Smarter Solutions’ approach delivers a process capability calculation that speaks the language of business—clear, predictive, and strategically aligned.

Process Capability Calculation Conclusion

When specification limits are missing or unclear, don’t abandon the idea of capability analysis—just calculate it smarter. By adopting the 30,000-foot-level approach, your process capability calculation becomes more meaningful, transparent, and actionable. This is not just a statistical exercise; it’s a key part of building a performance measurement system that drives real enterprise improvement.

What Does It Really Mean to Be Process Capable? A Smarter, Predictive Perspective

In many organizations, the term “process capable” is tossed around as a badge of operational success. But how do you really know if a process is capable—especially when formal specification limits are missing or when performance is evaluated against a business goal rather than hard specs? That’s where traditional metrics fall short, and a smarter solution is needed.

The Integrated Enterprise Excellence (IEE) system, developed by Smarter Solutions, provides a modern way to define and determine process capability through its 30,000-foot-level reporting. This method goes beyond outdated formulas and connects process behavior directly to business performance.

The Traditional View of Process Capability

Traditionally, a process is deemed “capable” when it consistently produces output within defined upper and lower specification limits. This evaluation relies on statistical indices such as Cp, Cpk, Pp, and Ppk—metrics calculated using the process mean, standard deviation, and spec boundaries. For example:

A process is considered capable if Cpk ≥ 1.33, which implies most data points fall within spec limits, assuming normality and control.

However, this view assumes:

You have clear specification limits.

The process is stable (in control).

The data is normally distributed.

These assumptions don’t always reflect reality.

When Performance Goals Replace Specifications

In many modern business environments, you may only have a performance goal, such as “respond to customer inquiries within 4 hours,” without a formal upper or lower limit. In this case, how do you determine if your process is process capable?

This is where the 30,000-foot-level approach redefines capability.

The 30,000-Foot-Level Redefinition of “Process Capable”

Instead of relying on assumptions that may not hold, the 30,000-foot-level methodology assesses whether a process is stable and predictable. Once stability is confirmed, a probability-based prediction can be made for future performance relative to the business goal.

Here’s how the smarter “process capable” determination works:

Evaluate Stability Over Time: Use time-ordered data charts to determine if the process is consistent or exhibits special cause variation.

Fit a Distribution (If Stable): Once the process is deemed stable, a distribution (e.g., normal, lognormal, Weibull) is fitted to the data, even if the distribution is not normal.

Report Predictive Performance: Instead of quoting Cp or Cpk, report the percentage of future outcomes expected to meet the goal. For example:

“Based on the fitted model, 96.7% of future cycle times are expected to be under the 4-hour target.”

This method removes ambiguity and better supports decision-making at all levels of the enterprise.

Conclusion: Capability That Matters

Being process capable isn’t just about meeting statistical definitions—it’s about confidently and predictively meeting what matters most to the business. The 30,000-foot-level methodology turns vague or incomplete performance expectations into clear, data-driven insights.

By redefining “process capable” in terms of predictable performance against business goals, Smarter Solutions provides a framework that aligns operational metrics with strategic impact—delivering insight, not just numbers.

Enhancement of KPI and Performance Metrics Reports: 30,000-foot-level reporting

Key Performance Indicator (KPI) and Performance Metrics Reporting benefits when these reports use a 30,000-foot-level format described in “KPI and Performance Metrics Reporting 2.0.”

Integrated Enterprise Excellence (IEE) Business Management System for Addressing a Process Capability Need that is a Customer Driven or a Goal

The Integrated Enterprise Excellence (IEE) business management system provides, among other things, 30,000-foot-level metrics that can be in alignment with the processes that create them throughout an organization.

You can create a 30,000-foot-level report for your dataset using a free 30,000-foot-level reporting app.

IEE addresses the business scorecard and improvement issues described in a 1-minute video:

How to select improvement projects so that the “big picture” benefits is described in How to Identify and Select Lean Six Sigma Projects: An Enhanced Approach.

IEE is described in:

- Article: Positive Metric Performance, Poor Business Performance – How Does this Happen?

- Video: Positive Metric Performance, Poor Business Performance – How Does this Happen?

The details of implementing the IEE system and its process capability analysis metrics throughout organizations is described in a 2-book, novel written series:

Books (Audio, Paperback, and E-book) Amazon Availability

- Management 2.0: Discovery of Integrated Enterprise Excellence (Management and Leadership System 2.0 Book 1)

- Leadership System 2.0: Implementing Integrated Enterprise Excellence (Management and Leadership System 2.0 Book 2)

The details of reporting process capability analyses and making their improvement are provided in Lean Six Sigma: A Handbook and Solutions Manual for Green Belt, Black Belt and Master Black Belt Process Improvement Projects 2-book Bundle

Also described in this book is how to report process capability in easy to understand terms when data are not normally distributed, which occurs frequently in transactional processes.

Next Steps

Schedule a video meeting with Forrest to see how your organization could benefit from the IEE system and 30,000-foot-level reporting using one of your datasets.

If you do not see a suitable time in the Schedule a Meeting link below, email Forrest at [email protected].